DE1.8KW ISO20 220V Frässpindel Water Cooled ATC Spindle with HY 2.2KW VFD CNC Kit

DE1.8KW ISO20 220V Frässpindel Water Cooled ATC Spindle w/ HY 2.2KW VFD CNC Kit. For CNC Router Milling Lathe Engraving Machine. EU Customers don't need pay VAT or Tariff. 1 x 1.8KW 220V ATC Automatic Tool Change Water cooled spindle motor 24000rpm 80mm 400Hz.

1 x 2.2KW 220V/AC Inverter VFD (Huan Yang Brand). 1 x 2M Extension cable/control panel box. English user manual of spindle&vfd. 100% Brand New and High Quality!! Automatic tool changer electric spindle parametric curve graph. Automatic tool changer electric spindle technical parameters.Spindle blowing dust/seal gas pressure (MPa). Spindle gas seal gas flow.

Spindle static state pulse (µm). Motor windings Pressure test (V/M).

1000V/1 minute withstanding Voltage test. For castings, aluminum, glass, etc.The bearing of spindle use grease lubricated angular to contact bearings, can be achieved lifelong lubricating within the life cycle. The spindle use forced coolling mode to coolling motor, front and rear bearings. Coolant flow through the reasonable arrangement cycle watercourse of the spindle body, thus can take the heat generated of the spindle rotation speed, to achieve thermal equilibrium, let spindle temperature within a certain constant value.

External cooling device effect:maintaining a constant temperature of the coolant. The spindle built-in PTC 140 temperature sensor(Technical parameters are visible in other sections of this specification), you can read it anytime if you need to protect the motor temperature. The tool clamping methods:this spindle built-in automatic tool change device, shank form is ISO20. The system must ensure that the cooling water temperature of supply spindle is between 24-28 degree. Usually setting the flow switch in return pipe of the cooling system, to ensure the supply of spindle cooling water. In order to prevent water or impurities enters internal of the spindle, spindle will have gas sealing device, the gas seal machine must be started start with the machine at the same time. And the need to go through multi-stage filtration. The quality requirement of gas which is used in gas seals. Running-in program instructions Only all monitoring issued no failures operational signals, at the same time, all safety devices have been installed and working properly, then allow start spindle.Note: new or spindle which is not used for a long time must to be running slowly. First, start run spindle for half an hour as 25% of the maximum speed, then increase to 50% of the maximum speed, to run 15 minutes, finally, increase to maximum speed.

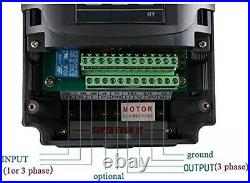

Its need to check the temperature of the spindle during the whole process, spindle will get hot, but not hot hand, if the spindle becomes hot, pls stop the operation and contact our customer service department. HY 2.2KW Variable Frequency Drive Inverter 220V 10A. 3 Input Frequency: 48-63 Hz.4 Output Frequency: 0-400 Hz. 5 Input Phase: 1 or 3 phase. 6 Output Phase: 3 phase.

R S T any 2 pins connect to 220V power supply. 1PID control; advanced calculus PID closed-loop arithmetic, quick responding speed and high suitability. 2Easy PLC function can realize 16 legs of speed and inverter control function. 3RS485 communication port, adopting standard international MODBUS main circuit control. 4With extremely strong anti-jamming capability. 5Low output ratting torque0.5HZ-150%, low speed running ability. 6Carrier adjustable by 16KHZ, completely soundless working environment. 7Broad voltage working area, normal running in 304V-456V.8Auto voltage regulation (AVR) technique, for ensuring the inverter load capability. 9Various control technique by both synchronization and non-synchronization, dynamically realize fast starting without changing brakes. 10With perfect errorprotection and short circuit starting protection capability.

Our company is an emerging professional Cross-Border Electronic company. We guarantee every product is of high quality and durable utility compared to other factories becayse we choose the best-buys goods.When you have the parcel, and not satisfied the goods or it is other problem like as broken, pls tell us the detail reason and provide the photos, we will help you to solve any problems. The item "DE1.8KW ISO20 220V Frässpindel Water Cooled ATC Spindle with HY 2.2KW VFD CNC Kit" is in sale since Thursday, October 14, 2021. This item is in the category "Business & Industrie\Automation, Antriebe & Motoren\Elektromotoren\Servomotoren". The seller is "powace1515" and is located in Lausanne. This item can be shipped to European Union member countries, United Kingdom.

- Marke: RATTM MOTOR

- Herstellernummer: Does not apply

- Power: 1.8KW

- Speed: 12000-24000rpm

- Frequency: 0-400Hz

- Cooling: Water cooling

- Pole: 2 Pole

- Size: 80x367mm

- Herstellungsland und -region: China

- Voltage: 220V

- Model: RTM80-20-24Z/1.8 - 220V

- Lubrication: Grease